WhatsApp: 0086 15522419684

Email: info@hx-machinery.com

Mobile No.:0086 15522419684

Tel:+86 022 86728681

Fax:+86 022 86728681

Add:1411, Chuangzhi Building, Tianjin, China

Size accurate, and seamless lap joint

Various shapes can be customized, beautiful version

Fast production speed and high work efficiency

Automatic control to reduce labor costs

Processed by stable operation, high precision and long service life.

Email: info@hx-machinery.com

WhatsApp: 0086 15522419684

Roofing Sheet Crimping Machine

The Roofing Sheet Crimping Machine is a specialized device used to create arched or curved panels from preformed metal roofing sheets. This machine is ideal for producing arch roofs, awnings, domes, and curved eaves commonly seen in warehouses, hangars, and stadiums.

It works by gradually crimping the edges of trapezoidal or corrugated roofing sheets to form a smooth, consistent curve without damaging the paint or protective layer. The machine is compatible with galvanized, color-coated, and aluminum sheets of 0.3–0.8 mm thickness.

The machine features a simple yet durable structure, user-friendly controls, and fast adjustment for different curvature radii. Equipped with a hydraulic system and manual or PLC-based control, it ensures accurate performance and minimal maintenance.

This crimping solution supports existing roll forming production lines, allowing manufacturers to offer custom curved roofing solutions without replacing their core systems. Haixing provides technical support, training, and customization options to meet specific project needs.

Choose Haixing's roofing sheet crimping machine for flexible, efficient, and high-quality arch panel production.

Contact us today to get a free quote and technical consultation.

Contact us today to get a free quote and technical consultation.

Roofing Sheet Crimping Machine

| Formed Material | GI/GL, PPGI/PPGL |

| Thickness | 0.3-0.8mm |

| Width | 1200mm(customized) |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 3 rows (As your requirement) |

| Diameter of shaft | 70mm solid shaft |

| Material of rollers | 45# steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58℃-62℃ |

| Power | 5.5+5.5KW |

| Control system: PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 220V 60Hz 3Phase (As your requirement) |

| Forming Speed | 10-15 m/min (The speed depends on the shape of the tile and the thickness of the material.) |

Looking for a reliable roofing sheet crimping machine?

Why Choose Us

28 years of professional R&D team

One-stop-solution for roll forming machine

Long-life stable running

High-precision finished products

High-quality raw materials

Brand electrical parts

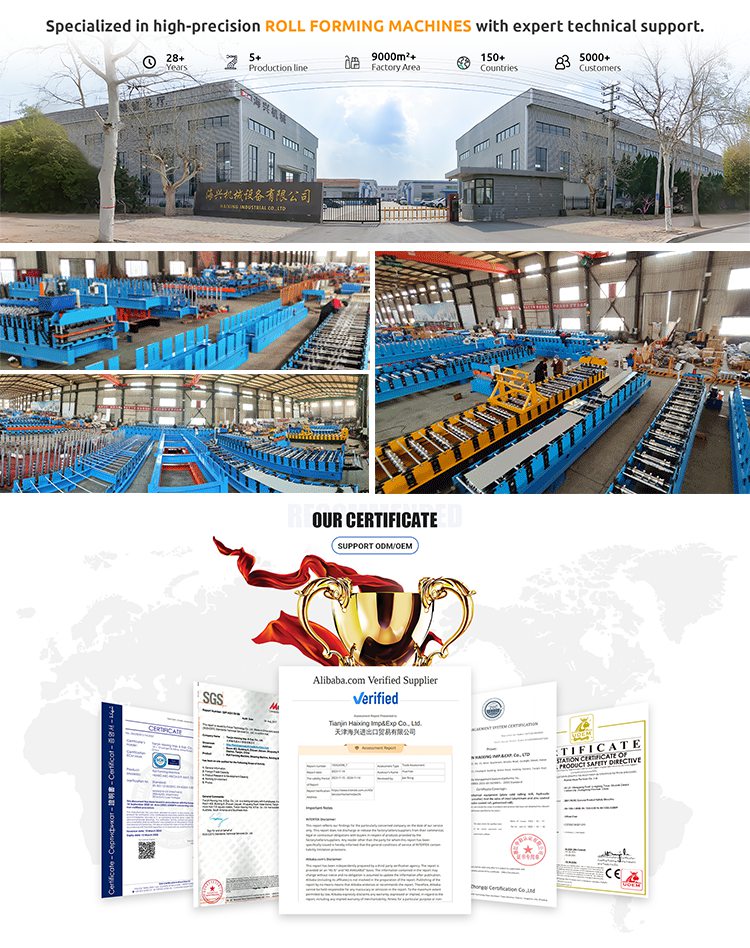

About us

Since 1996 year, Haixing Indrustry Group main products have evolved from a standard roll forming machine to a customized automated roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.

FAQ

Q:Are you manufacturer?

A:Yes,we are manufacturer for cold roll forming machine over 28 years.

Q: if you can accept OEM? Design and manufacture according our photo.

A: Yes, we can accept OEM,we owned expert engineer team, and use famous brand components according your demands.

Q:What's the warrany for our machine?

A: we provide 2 years guarantee and provide lifetime technical support.

Q:How many workers is needed for the machine operation?

A: One worker is engough, the machine use automatic PLC control system.

Q.Can you be responsible for transport?

A.Yes,we owned expert export team, we can arrangement for you to your destination port or address.

Q:What service can you provide before order?

A:About the pre-sale service, We provide professional solutions according your demands, such as design, technical parameter, delivery flow etc. at the same time, we can supply invitation letter for your visit our factory and know more our factory.

Q: What is the after- sale service?

A: we will supply lifetime technical support and supply quick-wear parts within 2 years.

Q: What's the delivery time?

A: 25 days after deposit receipt your payment

Q: Installation and training?

a.If buyers visit our factory and check the R BPR AG roof panel roll forming machine, we will teach you how to install and use the

machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

c.If buyer needs our technician to go to your local factory, we could go abroad to guide you for free, but you should pay the transportation and accommodation expenses.