WhatsApp: 0086 15522419684

Email: info@hx-machinery.com

Mobile No.:0086 15522419684

Tel:+86 022 86728681

Fax:+86 022 86728681

Add:1411, Chuangzhi Building, Tianjin, China

Size accurate, and seamless lap joint

Various shapes can be customized, beautiful version

Fast production speed and high work efficiency

Automatic control to reduce labor costs

Processed by stable operation, high precision and long service life.

Email: info@hx-machinery.com

WhatsApp: 0086 15522419684

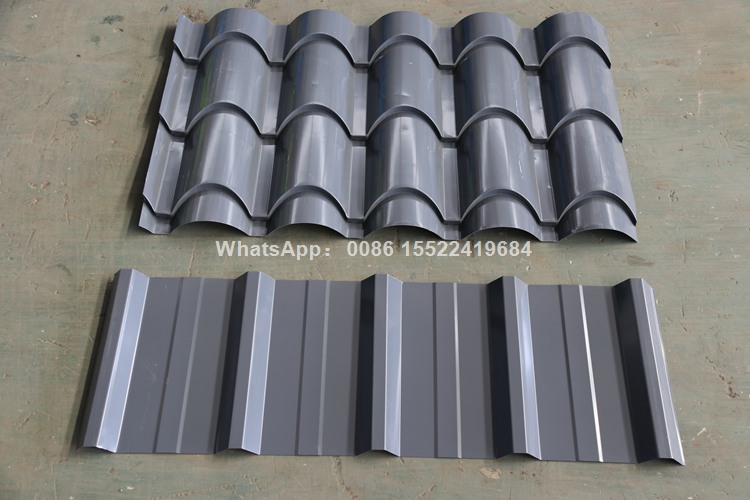

Roof Panel Roll Forming Machine – For Trapezoidal Sheets & Glazed Tiles

This dual-purpose roof making machine is designed to produce both trapezoidal roofing sheets and glazed roof tiles on a single line. It features a double-layer roll forming system with PLC control, hydraulic cutting, and automatic profile switching. Suitable for galvanized, color-coated, and galvalume steel coils, this machine is ideal for various roofing applications across residential, commercial, and industrial projects. With precise forming and customizable designs, it offers a cost-effective solution for diversified roofing production.

Contact us to get a more favorable roof making machine price!

Contact us to get a more favorable roof making machine price!

Roof making machine for Trapezoidal panel and Glazed tile

| Formed Material | GI/GL, PPGI/PPGL |

| Thickness | 0.3-0.8mm |

| Width | 1000mm(customized) |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 14 rows (As your requirement) |

| Diameter of shaft | 70mm solid shaft |

| Material of rollers | 45# steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58℃-62℃ |

| Power | 5.5+4KW |

| Control system: PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50Hz, 3Phase (customizable) |

| Forming Speed | 8-15m/min (The speed depends on the shape of the tile and the thickness of the material.) |

Looking for a reliable Double layer metal roofing roll former machine price?

Why Choose Us

End-to-End Solutions – Comprehensive engineering support from design to production

Extended Operational Lifespan – Robust machines built for long-term reliability

Micron-Level Precision – Consistent accuracy in finished products

Premium Materials – High-grade components ensuring structural integrity

Top-Tier Electrical Systems – Industry-leading automation and control components

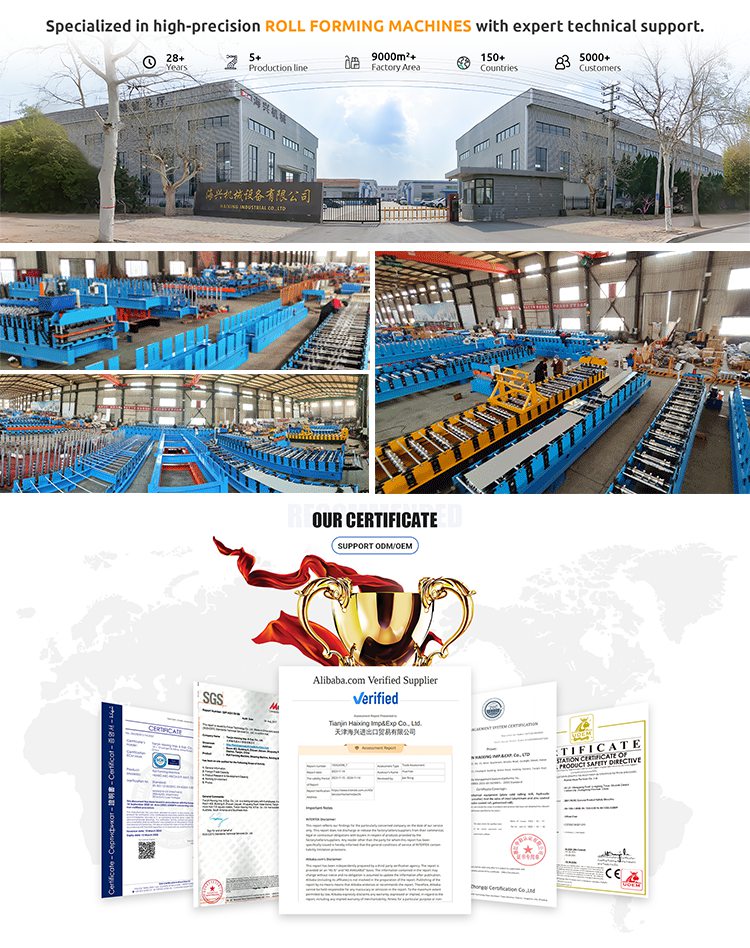

About us

Haixing Industry Group | Precision Roll Forming Solutions Since 1996

From standard roll forming machines to fully customized automated production lines, Haixing has partnered with over 5,000 clients across more than 150 countries. We deliver tailored solutions with:

Core Philosophy: Integrity as our foundation, win-win as our goal

Service Commitment:

Customer-first approach

Uncompromising quality standards

End-to-end professional support

Lifetime after-sales priority

Global Expertise. Trusted Efficiency.

FAQ

Q:Are you manufacturer?

A:Yes,we are manufacturer for cold roll forming machine over 28 years.

Q: if you can accept OEM? Design and manufacture according our photo.

A: Yes, we can accept OEM,we owned expert engineer team, and use famous brand components according your demands.

Q:What's the warrany for our machine?

A: we provide 2 years guarantee and provide lifetime technical support.

Q:How many workers is needed for the machine operation?

A: One worker is engough, the machine use automatic PLC control system.

Q.Can you be responsible for transport?

A.Yes,we owned expert export team, we can arrangement for you to your destination port or address.

Q:What service can you provide before order?

A:About the pre-sale service, We provide professional solutions according your demands, such as design, technical parameter, delivery flow etc. at the same time, we can supply invitation letter for your visit our factory and know more our factory.

Q: What is the after- sale service?

A: we will supply lifetime technical support and supply quick-wear parts within 2 years.

Q: What's the delivery time?

A: 25 days after deposit receipt your payment

Q: Installation and training?

a.If buyers visit our factory and check the R BPR AG roof panel roll forming machine, we will teach you how to install and use the

machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

c.If buyer needs our technician to go to your local factory, we could go abroad to guide you for free, but you should pay the transportation and accommodation expenses.